The information for this page has come from several sources:-

Michael Hurley provided some of the text in an Email to the Irish beekeeper's Discussion group.

The majority of the information came from a large sized scale drawing provided by Ben Harden. (click on the facsimile of his business card to Email him)

The Links at left are pages that have drawings and descriptions that have been produced from this 'Master Drawing'.

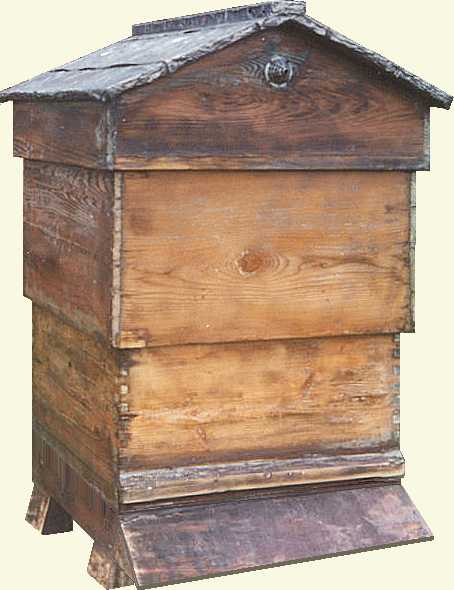

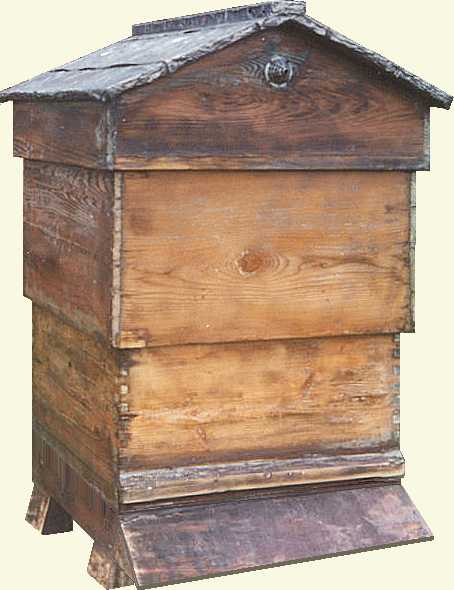

The Photograph was originally taken by Michael Clancy, I have edited it somewhat, but it is still a large file and may take some time to load.

The initials... 'CDB' need some explaining, they stand for 'Congested Districts Board'. The precursor here

is the Land Act of 1881 (which was introduced to help the then tenant farmers in Ireland). While this act helped those on larger

holdings, it was of little use to the smaller farmers along the West and South coasts of Ireland. Thus, ten years later in 1891,

the Congested Districts Board was set up (which also had responsibilities in Scotland).

Finance was given to help the fishing industry by providing Harbours and Piers. Cottage Industries such as lace making and carpet making were also funded as were weaving and homespun cloth. Attention was also given

to beekeeping by subsiding the cost of the hives and funding was made available to instructors in beekeeping.

The CDB Hive was designed by Abbott Bros... Who had premises in Dublin. The year was 1894 and the design was intended to suit the particular requirements of the Congested Districts Board.

The hive that was manufactured and sold by Abbott Bros. was specifically designed to withstand the wind and rain that is associated with that part of Ireland.

To aid the roof to stay in place it was A-shaped with a ridge piece on the top of the 30 degree slope. The relatively deep skirt to the roof gave weight in order that it did not blow off so easily as other

types. (The one photographed by Michael Clancy, illustrated above, is covered in lead sheeting which would also help to retain it in place.)

The floor was combined with the stand which has four splayed legs of about nine inches, similar to the

WBC hive. It was most decorative, but some may consider it challenging for home manufacture.

It was designed for section production, which was the norm at the time. It had a brood box designed to hold 11 Abbott

style British Standard frames and one 'dummy'... These were placed the 'warm' way. The brood box had a rain

shedding 'porch' which overhung the alighting board.

The use of the word dummy is different to the emphasis that we place on the term today... We would consider it a 'division board' because it occupies the full internal dimensions of the box it fits inside. Whereas we

would consider it a 'dummy' if it were the same overall dimensions as a frame.

Sections crates took the place of supers... These went inside the lift, but straight on top of the brood chamber. No mention is made of queen excluders in the original specification.

An alternative to section crate(s) was provided by 'doubling boxes', also known as 'super boxes', these were similar (but not identical) internal dimensions as brood boxes, but of thinner material so that they would fit in place of section crates inside the lift.

There was an ingenious lift which was larger in plan than the brood box and was held in position by internal cleats, so that the lift overlapped the brood box by half an inch, (there is a lot of wind from the Atlantic ocean on the West coast and South coast of Ireland). This lift could be reversed to give the effect of a double wall shrouding the brood box during the wet and windy winter.

When neatly painted it was a most decorative addition to the vegetable and fruit gardens of the time.

I am impressed by the fitness for heavy weather that this beehive offers and consider that many of it's robust features may suit present day honey production that is based on static sites. However there are many parts that are made from broad thin pieces of timber that would tend to warp badly if made from modern poorly seasoned timber. This could be overcome by using waterproof 'far eastern' plywood for such parts. The floors would need a minor re-design to incorporate much larger (full area) mesh screens and some runners to accommodate varroa

sticky boards. It uses more timber than a National hive,

but the extra weight and weather resistance would justify this additional cost in those areas where bad weather is

encountered.

Dave Cushman.

Page created pre-2011

Page updated 04/12/2022