The Beekeeper's Smoker

The smoker is a simple device for burning fuel in an environment that is starved of oxygen, until the bellows provide a mild blast of air. The two copper versions illustrated have different sized barrels, the smaller one at left has adiameter of 75 mm (3") and a height of 175 mm (7"), while the larger of the two is 100 mm (4") by 250 mm (10"). The two illustrations are depicted to a similar scale. The bent nose pattern was designed by Bingham and is also known as the 'Empire' type.

Use the smoker sparingly... Allow the prevailing wind to drift the smoke onto the bees.

Copper is a material that smokers have been traditionally made from, but tinplate, galvanized steel and stainless

steel are also common. Stainless steel is more robust and corrosion free, copper is also corrosion free, but the heat anneals the metal making it prone to damage (I have a copper one that has a very battered appearance).

Inside the base of the firebox thereis a 'grate' that gives a ventilated false floor at about 35 mm

(1 3/8") height.

The smoker illustrated at right is made of stainless steel and has the same barrel size as the one above right.

The barrel size of smokers varies, but certain combinations of height and width have been recognised, 180 mm and 250 mm are common heights, 75 mm and 100 mm are common diameters. These dimensions are used in any combination. Both larger and smaller types have been used, but the dimensions given account for about 90% of

English speaking countries' manufacture.

Some smokers are fitted with a grid or cage surrounding the firebox to act as a safety guard, as this small sized copper one illustrated at right. A simple guard made from a "U" shaped piece of sheet metal is sometimes combined with a hook so that the device can be hung on a hive box edge when not in actual use... Perhaps I am lucky, I have never used such a guard and I have not had any accidents.

I have seen many 'home made' bee smoker guards... Usually fashioned from a portion of a tin can and screwed direct to the front face of the bellows. In appearance these were rather like the stirrup or "U" shaped guard that occurs in the drawing of the straight nozzle older English style, further down the page.

The 'Etna' type is a version that has a hemispherically domed top. These are available in small and large versions, in tinplate, galvanized steel and stainless steel material and any of these forms is available with or without the wire guard cage.

I used one of these for a number of years myself... It was secondhand when I came by it and when I was begged to sell it, the buyer gladly paid 50% of the current new price. This is a good indication that it is a robust type that maintains it's value. The top is retained by a simple loop of metal rather than the full hinge of most British types. This results in much less of a forward projection and gives a much neater appearance if a guard is

fitted.

British made smokers of the early part of the twentieth century were smaller barreled, with fire boxes about 50 mm (2") diameter and about 125 mm (5") or 150 mm (6") long. These had straight nozzles and were used

with the barrel held horizontally. They have gone out of fashion, although some still do exist and are in use by a few 'old timers'.

I used a smoker of this type for well over 40 years. They had a reputation for not lasting long, but this was because critics didn't know how to use them. The best fuel I found was corrugated cardboard.

The best way to prepare it is to get it in large rolls if you can and there are plenty of sources. Roll it up loosely and stab it with a hive tool, then tear it up. This leaves a ragged edge that will light readily. Roll it up VERY tightly. Once alight I have often used it for well in excess of an hour before recharging. Next time you light it, just light the charred end and off you go again. It's a great pity in my view they aren't still made, but like a lot of good things in beekeeping they were rubbished by people who didn't know how to use them.

Roger Patterson

The cross section of the smoker. This diagram shows all the parts that are normally hidden from view, which include the bellows return spring and the firebox grate. Although not normally used in this type of smoker I have drawn the outline, in green, of the type of sleeve that is fitted within the Rauchboy firebox. I have actually tried this sleeve technique using empty fruit or vegetable cans to contain fuel such as pine needles and small pine cones, broken twigs and small off cuts of wood.

There is an adaptation, that some beekeepers make, to increase the efficiency of the bellows blast. It consists of a small tinplate or brass cone that is attached to the bellows over the air exit hole. This modification concentrates the air into a fine column that is aimed centrally along the venturi tube. The effect is two fold... first the narrow air column travels fast and thus travels further into the base of the firebox and secondly

the fast moving, lower pressure, air draws additional atmospheric air in with each blast thus increasing the volume of air delivered with each pulse of the bellows.

It is possible to make such a cone from stainless steel nozzles that are intended for icing cakes. I have personally used flanged brass cones, like the one at right, that are intended to maintain constant impedance on the rear of some "N" type coaxial cable sockets. These brass cones are flatter and less pointed than the one shown in red in the diagram above right, but they are just as effective.

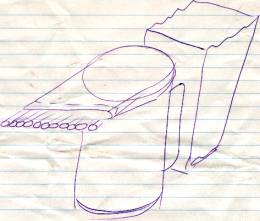

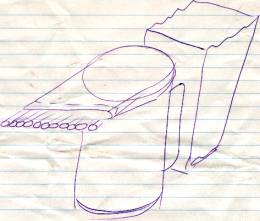

Duck's foot bee Smoker... 1979 I had an idea... (My original crude sketch is shown at right.) For a type

of smoker nozzle that would deliver smoke in a broad, flat, fan shaped cloud. A further advantage of this method was that the smoke would be cooled much more than with a conventional nozzle. The design of this actually evolved during the manufacture of the prototype. My original intention was to solder several thin walled brass tubes together side by side to form a set of parallel nozzles to broaden and flatten the cloud of smoke, much as shown in the sketch.

I obtained some thin walled brass tubing that was about 6 mm outside diameter. The tubing was in three individual lengths of 300 mm and so I cut each into four pieces about 73 mm long. My intention had been to

solder these together in parallel fashion, but I reasoned that if I tapped the rear ends of the tubes on to a square tapered mandrel I would achieve two useful things... The square mouths with flat sides would solder together with less gaps and in a much more solid fashion and by virtue of the shaping each tube would be slightly tapered so that the array of splayed nozzles became fan shaped. I used the tang of a 'rat tail' file as my tapered mandrel and my first attempt split the tube.

To correct this... I ground the mandrel to a narrower taper and rounded the sharp edges. Then with an

assistant holding a gas torch so as to just soften the brass, I managed to forge the rest of my tubes without any further loss, the illustration shows the tubes before and after swaging. The rest of the smoker was a standard tinplate one from stock that had a dented top.

This top was cut down with tin snips... The front edge was cut into fingers that were folded inwards to form a

platform that the fan shaped group of nozzles were soldered to. The splayed shape of the several nozzles gave rise to the name "Ducks Foot" as there was a historical type of pistol (click on the small picture at right for more details) that was intended for use against mutinous sailors, that had multiple splayed barrels... All

the barrels were discharged simultaneously, causing a fan shaped volley of balls.

The cover was made from a piece of thin brass sheet (source forgotten) that also had fingers cut around it's edge that were individually bent down and soldered. The splayed tubes were quite fragile and I supported them by soldering some 2.5 mm diameter copper rod across the upper and lower surfaces of the ends of the tubes. All the soldering was lead/tin plumbing solder and initially I was concerned that this may melt when the device was in use, but this did not happen. The device worked exactly as envisaged, but there was one snag... The tubes were narrow and very well cooled so that an inordinate amount of tar formed at the outer ends which turned to coke at the inner ends, requiring frequent cleaning. The solder has been omitted from the drawing, as a result of this... The drawing itself looks rather neater than the finished prototype did.

The "Rauchboy" smoker is a high quality, heavy duty device, designed by Hermann Link and manufactured by H. Tuerksch in Duisburg, it features a ventilated sleeve that contains the combustible material within the firebox. Heavily engineered and with leather bellows, it is designed for a lifetime of trouble free service.

More details are available, including spare parts, on the Rauchboy website (website unavailable on 10-07-2020. R.P.)

The inner sleeve, shown at left, is not quite to the same scale as the overall picture, but it fits in the fashion denoted by the green outline in the cross sectional drawing further up the page.

The bellows on all types of smoker used to be made of soft and flexible leather, similar to the Rauchboy

example, but the last few decades have seen the use of a plasticised cloth (Rexine) that is commonly used for upholstery, this is not so durable as leather and sometimes cracks, also the return springs in bellows can occasionally fail. I have had such a spring failure only once, in a secondhand unit that was at least ten years old. The bellows illustrated at right are offered by the appliance trade for such repair purposes, this type is made by E.H. Thorne in UK.

The air blast, that emanates from the hole that is evident in the bellows picture, is directed into a sleeve that is inserted in the side of the smoker barrel about half way up the void that exists under the grate.

This smoker has no bellows at all, it is spring driven (clockwork) and has a metal fan that provides the draught. It is known as a 'Vulcan' smoker.

Similar to the Vulcan there is an almost identical version that is powered by a torch battery.

Both of the bellow less smokers have switches or levers to allow the delivery of smoke to be regulated.

I used to sell both of these types when I was in business, but I would sell two or three hundred 'normal ones' to every clockwork or battery one sold.

I have been told by a friend that the battery version tends to overheat the battery, but I have no

personal experience of actually using either type myself.

In Germany, originally for use inside bee houses, an unusual smoker rather like a large metal smoking pipe has been developed. Known as an Imker Pfeife (beekeeper's pipe). It is used with coarse tobacco stalks or herbal smoking mixture, it is blown rather than sucked. The picture was taken from the website of

R. Meiers Sohne AG and I have hacked it about a bit... It shows the larger of two similar versions that are made of aluminium and have double walled fire boxes. The fuel that is shown alongside is coarse bee tobacco.

You can purchase beekeeping veils with reinforced apertures in a suitable place so that the smoker mouthpiece

will pass through. The red netting is just packaging material and is discarded before use.

I saw an unusual type thatwas made from a pair of fire drawing bellows... I believe that it was made in India and consisted of a horizontal pair of bellows with handles, with a firebox shaped rather like a cauldron mounted above the bellows intake valve. The smoke being drawn into the bellows and then expelled through the nozzle. This would have produced a cool smoke, but I expect a considerable deposit of tar would have built up on the inside surfaces of the bellows. The drawing shows the colours somewhat brighter than the original, the example that I saw was crimson and gold, but it was discoloured by smoke and dirt. This drawing was done from memory and may not be totally accurate.

Below are two methods of "smoking" bees without the use of the traditional smoker. There are several others. I have never used any of them, or even seen them used. Quite frankly the principle doesn't appeal to me, as I have plenty of smoker fuel available and I have never seen any reason to use anything else. I'm sure the use of proper smoke is far less cost to the environment.

Roger Patterson.

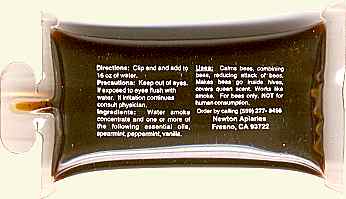

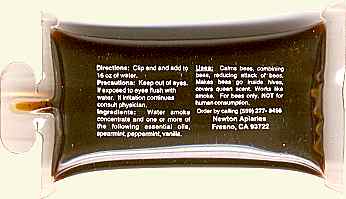

Liquid Smoke has been popular in recent years, it calms the bees very effectively. It is simply a sachet of

concentrated brown liquid that is mixed with water at a volumetric ratio of 1:16. The dilute working solution is then sprayed using a trigger bottle (like that used for misting plant leaves with water). The puffs of spray being used in a similar fashion to 'normal' smoke. It is a handy tool for swarm collection duties as it can be used in

areas such as flammable liquid storage units, garage forecourts and other places where a lighted smoker would not be allowed.

There are two disadvantages, to liquid smoke... First, you cannot use it to chase bees, in a particular

direction, as you can with conventional smoke. Second, the pungent spray leaves a stain behind that may contaminate either nectar or honey. Repeated use will cause a build up of such a stain on woodwork and as I am unsure of the analysis of the stain I cannot be certain that it is a good thing or even an innocuous thing to have in a bee hive. The warning " For bees only, NOT for human consumption" is displayed on the sachet. The ingredients, which are also listed on the sachet, state:- Water, smoke concentrate, and one or more of the

following essential oils... Spearmint, peppermint, vanilla. The sachet illustrated was supplied by Newton Apiaries, Fresno CA 93722.

Fabi-Spray "Cold Smoke" comes in an aerosol type canister and is ideal for simple manipulations that can be completed quickly. Just spray a small amount and the bees will retreat. This product saves the hassle of lighting the smoker for such 'in and out' type jobs.

The following wording has been taken off the website of an agent. The wording of most agents is similar:-

"An exceptional CFC free calming spray. Lift the crown board and give one short spray from about 12" and the results are amazing. Ideal for carrying out quick isolated inspections. One tin should last a season. It has a pleasant citrus smell, which evaporates readily. It is completeley harmless to the bees, brood and any honey present. HIGHLY FLAMMABLE"

When I was in business, we used to stock an aerosol smoke product called a 'Hive Bomb', I am not sure

whether this was just compressed and liquefied smoke or whether it was smoke dissolved in a volatile carrier gas. The smoke

was pungent, but I personally never tried one on the bees.

Dave Cushman.

Page created pre-2011

Page updated 10/07/2020