Electric Pump

|

|

|

|---|

|

Electric Pump |

Multi Dose Saline Driver Pump |

|---|

The pistons in conventional syringes are relatively large in diameter with a consequent

large delivery volume per millimetre of advancement.

The pistons in conventional syringes are relatively large in diameter with a consequent

large delivery volume per millimetre of advancement.

Some delivery systems seek to overcome this by using a micrometer type fine screw thread and calibrated thimble to advance the large piston by very small distances such that calibrated quantities of liquid are dispensed. Such systems work effectively, but are expensive and difficult for the shoestring financed to make at home.

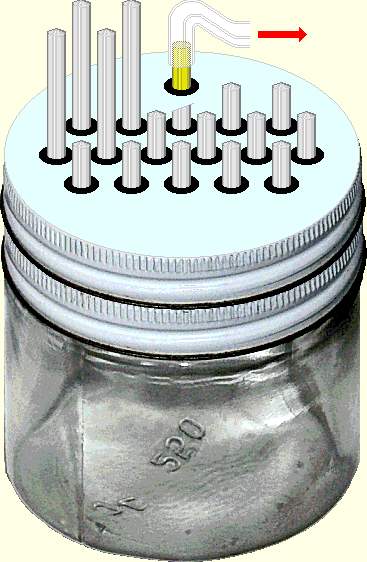

The device depicted here overcomes that problem by having multiple pistons, each of small diameter so that any one of them can be pushed individually into the syringe barrel by a calibrated distance and thus deliver individual amounts of saline that in turn displace semen in a capillary tube.

The drawing shows the concept rather than actual reality, as this device has never yet been constructed. It is envisaged that a glass ointment jar can be utilised as the main barrel with a metal screw on lid, allowing the thick rubber membrane to be trapped firmly in position by soldering a second lid (with identical drillings) direct to the first. The pistons are spaced in rows so that they can be activated individually and sequentially. It is hoped that the slab of rubber will be held firmly enough that the pressure caused by piston insertion is not modified or leaked away. The barrel of the device needs to be filled and the lid fitted under the surface of a large quantity of saline in a larger outer container, as no air bubbles can be allowed within the chamber. The ointment jar depicted here is 83 mm diameter and the lid is thought to be an R80 screw thread. The pistons are shown larger than they would be in reality for ease of understanding, so there would be more pistons per row and maybe more rows in an actual device. The rubber/neoprene disc can be sourced from industrial conveyor belt material or materials intended for the shoe repair trade, a rubber/plastics wholesaler would advise you what was available. The holes that the pistons are pushed through will need to be reasonably smooth in the bore, I think this can be achieved by using a stainless steel thin wall tube that is sharpened like a 'cork borer' and then spun in a pedestal drill with lubrication (surgical spirit with a small amount of engine oil would seem a likely lubricant). The feed tube for the saline drive line is shown as bras, because I have some brass tube that would do the job, but I would recommend stainless, maybe the same material as is used to bore the holes. The pistons themselves will need a smooth and polished surface, some sort of calibration mark on the pistons to aid delivery of specific volumes would be handy, I am of the opinion that chemical staining could be employed to do this, without damaging the surface finish, but it would require someone with a better knowledge of chemistry than I have, to advise on what this would entail.

|

The pistons are intended to be needle roller bearings, if I can track down some that are thin enough as well as long enough, but cobalt steel drill blanks are of the right rigidity and surface finish, and with regular polishing the individual pistons will improve in surface finish, with the result of easier and less jerky delivery. Bits and pieces can be obtained from many sources, the two packets illustrated at right were purchased at a fishing tackle shop and are respectively... pvc tubing that can be used to deliver saline and silicone rubber sleeves that can be used to couple plastic and glass tubing. They were not expensive, the pvc tube was £1.05 and the packet of silicone sleeves was £0.75 (2001 prices).

The clear plastic tube illustrated below near right came out of an inkjet printer that I

was dismantling for parts... |

|

|

|---|

|

The extreme right hand picture shows a surgical butterfly needle with tubing and leur fitting adaptor that will fit on the nipple of a syringe barrel |

Written... Summer 2001, Revised... 10 October 2001, Revised... 02 April 2002, Upgraded... 19 April 2007, Additions... 07 May 2007,

|